Features

Aercore 800

Aercore 800

The Aercore™ 800 is designed around simplicity, and that definitely applies to the ground-following system. In fact, it doesn't need a ground-following system at all.

If the coring head on any aerator were located anywhere other than precisely between the rear tires, a complex linkage system would be required in order to allow the coring head to float and follow undulations.

Take a tractor-mounted aerator for example. The aerator is located behind the rear tires. A float system is required to allow the aerator to follow the contours. As the tractor crests a hill, the natural tendency is to lift the aerator out of the ground. However, the three-point linkage and hydraulic floating system allows the aerator to follow the contours.

No such system is required on the Aercore 800. By locating the coring head precisely between the tires, the tining action perfectly follows the ground that is in contact with the rear tires. No complex linkages are required to enable the coring head to follow the contour. This also promotes consistency of hole depth across undulations.

Do you mow your greens with a 56-cm (22-in.) cutting unit, or do you mow them

with a 76-cm (30-in.) cutting unit? Most will agree that greens are mowed with 56-cm (22-in.) cutting units, or maybe even 45.7-cm (18-in.) cutting units. The 76 cm (30-in) cutting units are not acceptable for mowing greens.

Why do you mow greens with a narrower-width cutting unit? The answer is to eliminate opportunities for scalping, improving overall turf health and providing excellent cut quality. The narrower the cutting unit, the less risk there is of scalping the turf in an undulation.

The same principle applies during aeration. During aerification, you are looking to impact the top 3 in. to 4 in. (7.6 cm to 10.2 cm) of the soil profile. A narrow aerator is going to follow undulations much better than a wider one, keeping a more consistent depth throughout the aeration practice. A consistent depth means more compaction relief at the full depth of aeration and even more accurate topdressing applications.

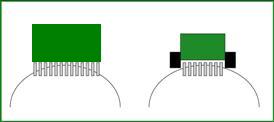

Depth comparison

Depth comparison

Look at the diagram above as an example. The picture to the left increases the width by 50 percent to 48 in. (123 cm), while the picture to the right shows the Aercore™ 800. Both are aerating on the exact same slope. As is shown, the wider aerator punches much shallower as you get to each end of the aerator.

Take particular note of the last two to three tines on each end of the 48-in. (123-cm) aerator that are significantly shallower than the outer tines on the Aercore 800. This means the top 3 in. to 4 in. (7.6 cm to 10.2 cm) you are trying to impact as part of the aeration process is now much less than that as you get farther from the aerator's center.

When calculating topdressing, this is significant. Now the calculation you have run at 3 in. to 4 in. (7.6 cm to 10.2 cm) of depth, based on square footage aerated, means you will have purchased excess topdressing, and more importantly, you will not have impacted as much of the soil profile as anticipated.

This diagram proves the John Deere Aercore 800 does a much better job of keeping depth consistent across the entire undulation. Just like a greens mower, a narrow walk-behind aerator provides greater consistency on undulating terrain in comparison to wider machines.

Verticutter attachment

Verticutter attachment

The verticutter attachment may be fitted to any Aercore 800 machine equipped with the 25-hp Kohler® Command Series engine.

The verticutter utilizes carbide-tipped blades and may be operated to a maximum depth of 1-3/4 in. (44.5 mm) in any of the Aercore 800’s four operating gears. Soil conditions will determine whether or not maximum depth can be achieved. A 31.5-in. (80-cm) width matches the aeration width of the Aercore 800. The standard blade spacing from the factory is 1 in. (25.4 mm), but it can be increased or decreased using spacers in increments of 1/4 in. (6.4 mm).

Featuring a precise, no-tool depth adjustment, the verticutter attachment allows superintendents to operate at virtually any depth up to 1-3/4 in. (44.5 mm). A convenient handle and transport bracket allows the operator to lift the verticutter to a higher position for transporting.

The verticutter utilizes a belt drive system that engages when the coring head is lowered and disengages when the coring head is raised. By utilizing the same electrohydraulic lift/lower system currently on the Aercore 800, an operator may raise the verticutter without the engine running.

Standard tire scrapers for the verticutter eliminate any debris buildup to maintain a consistent verticutting depth.

Once installed, the versatility of the verticutter attachment allows the operator to aerate only, verticut only, or simultaneously aerate and verticut. To aerate only requires simply disengaging the verticutter belt drive, located underneath the belt drive cover. Superintendents choosing to verticut only may do so by simply disengaging the two coring head belts and securing them with the provided belt latches.

Simultaneous application in process

Simultaneous application in process

Completed green

Completed green

Gas engine

Gas engine

The Aercore™ 800 utilizes a 25-hp (18.6-kW) gas engine. Why this much power with a 31.5-in. (80-cm) walk-behind aerator? There are two primary benefits.

The first benefit is the increased horsepower allows the engine to turn at a much-slower rpm on entry and exit when the throttle-back solenoid is turned on. The throttle-back solenoid slows the engine down on both entry and exit to eliminate tufting of the turf as the coring head lifts and lowers.

Turning the engine as slowly as possible without stalling is key. The increased power provides sufficient power to the coring head at a reduced rpm to further improve entry and exit hole quality. This reduced rpm is preset from the factory and, in most cases, should not need further adjustment.

The second benefit is the Aercore 800 offers an optional verticutter attachment to provide an industry-exclusive aerating and verticutting combination. This tandem offers a productive and versatile option that no other competitor can do.

The 25-hp (18.6-kW) engine allows the verticutter alone to operate at a depth of up to 1.75 in. (4.4 cm). Also, the increased horsepower allows the aerator and verticutter to be run simultaneously to impact even more surface area and further reduce compaction as part of the aeration process. Course conditions will dictate how deep the verticutter can be run in combination with a maximum aeration depth.

*At 3600 rpm. Engine manufacturer gross power per SAE J1940. Tested in accordance with

SAE J1995. The engine hp and torque information are provided by the engine manufacturer to be

used for comparison purposes only. Actual operating hp and torque will be less. Refer to the

engine manufacturer’s website for additional information.

Mechanical transmission

Mechanical transmission

Hydraulic leaks are a superintendent's worst nightmare. Not only do they have the potential to damage significant amounts of finely manicured turf, but in many cases, if the fluid is not biodegradable, the turf area must be dug up and replaced. Not to mention the dissatisfaction of the golfers who must play on unsightly turf that has been damaged by a hydraulic leak.

For that reason, the Aercore™ 800 Aerator features a mechanical transmission as opposed to a hydraulic traction drive system. A mechanical transmission eliminates hydraulic leak opportunities, providing confidence the aeration process will run smoothly.

The Aercore 800 uses a five-speed transmission—four aeration gears and one transport gear. The four aeration gears are as follows:

- First gear = 1.4-in. x 1.4-in. (3.6-cm x 3.6-cm) spacing (mini tines)

- Second gear = 2-in. x 2-in. (5.1-cm x 5.1-cm) spacing

- Third gear = 2.6-in. x 2-in. (6.6-cm x 5.1-cm) spacing

- Fourth gear = 2.9-in. x 2-in. (7.4-cm x 5.1-cm) spacing

A mechanical transmission ensures hole spacing will be consistent and precise across every aeration pass. The gear selector is conveniently located within the operator's reach for easy speed and spacing selections.

The transport gear on the Aercore 800 safely directs the machine away from the operator during transport at a speed of 3.5 mph (5.6 km/h). Some competitive units transport at a speed of 4 mph (6.4 km/h), with this speed coming directly toward the operator.

The integrated operator-presence bail system allows the operator to easily stop the machine by simply releasing the bail to bring the machine to a quick stop,should the need arise. In addition, the steering radius is limited in transport mode to provide even safer operation during transport.

Aercore 800

Aercore 800

The Aercore™ 800 was designed to be turf friendly. From adjustable turf guard pressure, to the Flexi-Link design, to the hydraulic-free mechanical transmission, the Aercore 800 is a market leader in turf friendliness.

But the design goes much further than just its key product features. The Aercore 800, including its innovative components, weighs only 1367 lb (620 kg), very lightweight for a very productive aerator. The next closest competitor in terms of productivity weighs 1590 lb (721 kg). The goal of aeration is to relieve compaction from everyday machine use, and John Deere has limited the compaction of the aerator itself by keeping the weight of the machine under control.

Even when you add the industry-exclusive verticutter attachment to the Aercore 800, it only weighs 1442 lb (654 kg), still nearly 150 lb (68 kg) lighter than the most-productive competitor.

Not only does the Aercore 800 offer a lightweight design, it also has a very low operating tire pressure to further spread out the footprint of the machine and minimize turf compaction. The Aercore 800 utilizes a tire pressure of 9 psi (62.1 kPa), where the closest competitor in its class in terms of productivity uses 12 psi (82.7 kPa) of tire pressure.

Electrohydraulic lift system

Electrohydraulic lift system

The Aercore™ 800 Aerator features an electrohydraulic lift and lower system. When looking at a typical hydraulic lift system alone, it means the engine must be running in order to lift and lower the coring head. The engine physically turns the pump that controls the hydraulic system.

Not on the Aercore 800. The Aercore 800 system goes beyond hydraulic — it also has an electrical component. Basically, this system features an electric motor that turns a hydraulic pump to engage a hydraulic cylinder for raising and lowering the coring head.

If the machine runs out of gas or there is an engine failure during aerification, raise the coring head out of the ground by simply leaving the key switch in the run position and pressing the lift switch. Or simply release the operator-presence bail and the head automatically raises out of the ground. No need to break out the tools and start removing tine holders and turning hydraulic dump valves to remove the machine from the green.

The coring head must be raised to start the engine on the Aercore 800. Therefore, an automatic feature has been built in that, if an operator tries to start the engine with the coring head in the down position, the electrical system raises the head as soon as the key is moved to the run position to prepare for starting. All of this is done electrically and does not require the engine to be running.

Aren't hydraulics bad for greens if they leak? Yes, but not on the Aercore 800. The hydraulic fluid on the Aercore 800 is biodegradable. If it leaks, it does not need to be removed from the turf. Plus, since the only function is to lift and lower the coring head, it is not constantly being used, keeping the oil cool and preventing any heat damage should the system leak.

The speed at which the electrohydraulic lift/lower system operates also optimizes entry and exit hole quality. The head raises and lowers very quickly, getting the tine perpendicular to the turf as quickly as possible.

Core deflectors

Core deflectors

Standard drive tire core deflectors eliminate running over pulled cores from the previous aerification pass. The deflectors lift and lower with the coring head and push aside any cores that may lie in the path of the drive tires. They also float freely to follow even the most undulating greens.

By preventing the tires from running over pulled cores, the drive tire core deflectors improve the green cleanup process after aerification.

It is important to note it is not an issue to run over previously punched holes with a walk-behind aerator. All greens require a cleanup and topdressing process once aerification is complete. People and machines are used on the greens to pick up cores and distribute topdressing, so the newly punched holes will get run over several times before the topdressing is put down.

The key issue is to ensure cores are not mashed down into the turf, hurting the effectiveness of the cleanup process and filling holes with undesirable material. The drive tire core deflectors do an outstanding job of making sure your greens are ready for the cleanup process, ensuring a more effective topdressing application that fills the new holes with desirable amendments.

Coring head belt drive

Coring head belt drive

Verticutter belt drive

Verticutter belt drive

The Aercore™ 800 and its optional verticutter attachment feature a belt-driven design, providing quiet and smooth operation that does not require any lubrication. Belts require very minimal maintenance compared to traditional chain drive systems.

Chains require lubrication to keep them running efficiently, and no golf course wants to have the opportunity of dropping excess grease on golf course playing surfaces. Belt drive systems only require proper belt tension and regular cleaning to limit debris buildup.

To further enhance serviceability, the Aercore 800 features sealed bearings throughout the entire coring head system. This simplifies maintenance and, once again, ensures excess grease is not dropped onto playing surfaces.

The belt drive system uses a cogged belt and cogged pulley. This makes it possible to time the coring head, limiting machine vibration and ensuring a perfect hole pattern.

Timing the Aercore 800 is simple. Loosen both coring head idler pulleys so the belts can be moved away from the cogged pulleys. Use the bottom of the turf guards or a reference point on the frame to line up the outside two arms with one another. Naturally, the inside arms should be closely lined up as well. Slip the belts back on and tighten up the idler pulleys at the proper belt tension. The Aercore 800 is now in time.

The matched pair of cog belts provides long life and requires minimal adjustments. Even the occasional belt replacement is made easy by having all the belt drive components located on top of the machine where they are easily accessible.

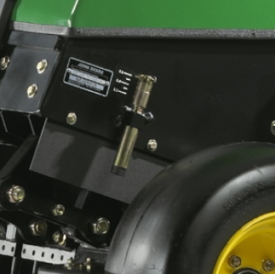

Aeration depth adjustment

Aeration depth adjustment

Verticutter depth adjustment

Verticutter depth adjustment

The Aercore™ 800 utilizes a pin and spacer system to establish aeration depth. This provides a simple system that is both easy to use and requires no tools for adjustment.

Once adjusted, the depth adjustment rests on the Aercore 800 frame when the coring head is lowered. By resting the depth adjuster against the frame, this ensures the depth of the hole is consistent across the surface being aerated. There are no electronic sensors or linkages to rely on when establishing the depth on the Aercore 800.

The depth adjustment on the optional verticutter attachment also requires no tools for adjustment. Just loosen the locking nut using the attached lever, and move the wheel up or down until it lines up with the desired depth.

Because the verticutter counterrotates to the direction of travel, the blades are always being pulled into the turf. Therefore, you do not have to be concerned about the verticutter depth changing during operation.

Specs & Compare

Key Specs | Aercore™ 800 Current Model |

| Horsepower | AT 3600 rpm: 18.6 kW 25 hp Engine Manufacturer Gross Power per SAE J1940. Tested in accoradance with SAE J1995. The engine hp and torque information are provided by the engine manufacturer for comparison purposes only. Actual operating hp and torque will be less. Refer to the engine manufacturer's website for additional information |

| Swath width | 800.1 mm 31.5 in. |

| Attachments installed | Tines; verticutter |

| Lift system type | Electro-hydraulic, electric pump, single hydraulic actuator; does not require engine to be running to lift/lower |

Engine | |

| Manufacturer/model | |

| Horsepower | AT 3600 rpm: 18.6 kW 25 hp Engine Manufacturer Gross Power per SAE J1940. Tested in accoradance with SAE J1995. The engine hp and torque information are provided by the engine manufacturer for comparison purposes only. Actual operating hp and torque will be less. Refer to the engine manufacturer's website for additional information |

| Cycle | Four |

| Displacement | 725 cc 44.2 cu in. |

| Fuel capacity | 18.9 L 5 U.S. gal. |

| Fuel mixture | Regular unleaded, leaded |

| Ignition | Solid State |

| Air filter | Dual stage |

| Starter | Electric/Solenoid |

Transmission (Coring) | |

| 1st gear | Mechanical |

| 2nd gear | Mechanical |

| 3rd gear | Mechanical |

| 4th gear | Mechanical |

Transmission (Transport) | |

| Speed | 5.6 km/h 3.5 mph |

Tires/Wheels | |

| One steer tire | 20x10-10, 55-69 kPa 20x10-10, 8-10 psi |

| Two drive tires | 20x10-10, 55-69 kPa 20x10-10, 8-10 psi |

Coring Swath | |

| Swath width | 800.1 mm 31.5 in. |

Coring Head Drive | |

| Type | Matched dual V-belts |

Lift System | |

| Type | Electro-hydraulic, electric pump, single hydraulic actuator; does not require engine to be running to lift/lower |

Productivity | |

| 1st gear | 11,025 sq ft/hr 1024 sq m/hr |

| 2nd gear | 15,750 sq ft/hr 1440 sq m/hr |

| 3rd gear | 20,710 sq ft/hr 1933 sq m/hr |

| 4th gear | 22,835 sq ft/hr 2123 sq m/hr |

Coring Depth | |

| Range of depth | Up to 88.9 mm 3.5 in. |

Coring Patterns | |

| 1st gear | With mini tines: 36x36 mm 1.4x1.4 in. |

| 2nd gear | 50x50 mm 2.0x2.0 in. |

| 3rd gear | 65x50 mm 2.6x2.0 in. |

| 4th gear | 75x50 mm 2.9x2.0 in. |

Operator Presence System | |

| Availability | Standard |

Dimensions | |

| Weight | 595 kg 1312 lb |

| Height | 1110 mm 44 in. |

| Width | 1473 mm 58 in. |

| Length | 2134 mm 84 in. |

Sound Levels | |

| Operator ear | With tines only: 85 dBA With tines and verticutter: 86 dBA |

| Measuring standard | ISO 11201 |

| Attachments installed | Tines; verticutter |

Additional information | |

| Date collected |