Features

NOTE: Only for single spindle and multi-spindle.

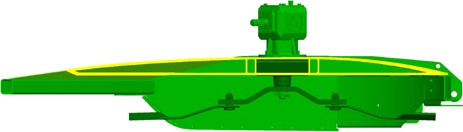

John Deere rotary cutters lead the way with innovative design, superior performance, and proven durability. Valuable features such as the Double-Decker™ design and Max Flow cutting chamber prevent water and debris from accumulating on the smooth, dome-shaped top deck while the flat bottom deck absorbs the punishment from rocks and stumps.

The top deck stays smooth - no dents, no dings, no holes. The internal supports sandwiched between the top and bottom decks are key to the smooth and structure-free Max Flow cutting chamber, while at the same time provide added strength and durability.

To help promote safe operation, John Deere rotary cutters are equipped with front and rear safety-chain shields. John Deere rotary cutters continue to advance in value with powerful gearboxes, blade holders, and compatibility with a wide range of tractors.

Here are situations when a rotary cutter provides value:

-

Clipping pastures encourages grass growth, optimizing valuable pasture acreage.

-

Cutting grass and stalks helps control insects.

-

Routine cutting keeps weeds from reseeding.

-

It is the most cost efficient way to cut roadsides, parks, cemeteries, airport fields, hydro, gas, and telephone easements, and all other types of open properties.

-

Cutting grass waterways encourages root development and helps prevent erosion.

-

Knocking down stalks such as cotton, corn, or milo speeds up decomposition. This is essential in no-till and minimum-till fields.

-

Clearing out brush.

-

Control undergrowth and grass in orchards, vineyards, and groves.

Decide what model to use based on:

- The size of the area to mow versus the size of the machine – the bigger the area to mow, the bigger the mower needs to be in order to be efficient during mowing hours. Similarly, the limitation of a small area will guide operators to use a smaller mower.

- The amount of time and frequency it will be used – for longer hours and more frequency, choose a heavier duty machine.

- Tractor compatibility – if there is a tractor the operator will be using, look for the tractor compatibility sheet to identify appropriate options.

John Deere rotary cutters are available in two duty-level categories:

-

Mid-duty

-

RC M models are available in 1.5-m (5-ft), 1.8-m (6-ft), 2.1-m (7-ft), 2.5-m (8-ft), and 3.2-m (10-ft).

-

This duty-level category cuts brush up to 50.8 mm (2 in.) in diameter.

-

-

Heavy-duty

-

RC R models are available in 3.2-m (10-ft) and 4.2-m (14-ft).

- This duty-level category cuts brush up to 76.2 mm (3 in.) in diameter.

-

RC6R is available in 1.8-m (6-ft) and the RC7R is available in 2.1-m (7-ft) cut widths; they cut brush up to 101.6 mm (4 in.) in diameter.

-

NOTE: R Series are heavier built to cut at a 101.6 mm (4 in.) capacity level more frequently and for longer durations.

Cross-section of Double-Decker design

Cross-section of Double-Decker design

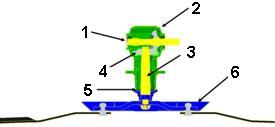

Replaceable bolt-on skid shoes

Replaceable bolt-on skid shoes

The patented Double-Decker design improves strength and cutting performance while reducing top deck rust. Two welded decks include a 3-mm (11-gauge, 0.118-in.) to 3.5-mm (10-gauge, 0.138-in.) thick upper deck, depending on the model, and a 3-mm (11-gauge, 0.118-in.) to 4.5-mm (7-gauge, 0.177-in.) thick lower deck, depending on the model.

Internal stiffeners are sandwiched between the decks to add extra strength and rigidity.

The Double-Deck design also provides a sturdy base to support the gearcases. Gearcases need this sturdy base to resist the bending loads imposed upon them when blades contact immovable objects or the ground.

The bottom deck is the main defense against rocks and field debris, to help protect the top deck from impacts so it will retain its smooth form.

Each side skirt includes replaceable bolt-on skid shoes.

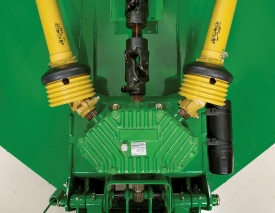

Gearcase and blade holder shown

Gearcase and blade holder shown

The John Deere RC gearboxes:

- Large seals

- Large housing

- Large output shaft

- Precision forged bevel gears

- Large bearings

- Stump jumper

RC gearcases and blade holders provide the following:

-

More horsepower

-

Faster blade-tip speed

-

Better performance

-

Quieter operation

-

Increased durability

RC10R gearcases

RC10R gearcases

Gearcases are John Deere engineered for reliability and dependability.

- Transfer (center gearcase) – 120 continuous hp or 180 peak hp

- Outer gearcases – 100 continuous hp or 140 peak hp

Heavy-duty, tapered roller bearings and precision gears help ensure long life.

Output shafts are splined, not just keyed, for extra strength and durability.

The RC10R model comes standard with five year warranty.

Suction blades

Suction blade

Suction blade

Suction blades provide additional lift action for picking up downed material. The blades are 1.3 cm x 10.2 cm (0.5 in. x 4 in.) in size and heat-treated for long wear life.

A fast blade-tip speed (up to 16889 fpm) ensures clean cutting and fine shredding of material.

Flat blades

Flat blade

Flat blade

Flat blades are effective for any materials not downed and require suction for lifting.

Flat blades require less horsepower and have a cutting edge on both sides. Only available with double-blade system.

Dual blades (bar-type blade holder only)

Dual blades

Dual blades

Dual blades are effective for increased shredding of crop residue.

The dual blades consist of a 1.3-cm x 10.2-cm (1/2-in. x 4-in.) lower suction blade and a 1.3-cm x 7.6-cm (1/2-in. x 3-in.) upper suction blade.

Lift type

Lift type (shown with iMatch™ hitch system)

Lift type (shown with iMatch™ hitch system)

The lift-type versions fit tractors with Category 2, 3, or 3N 3-point hitches (with or without Quick Hitch).

NOTE: The lift-type versions require a larger tractor than other versions. For RC10R Lift-Type Rotary Cutters, the minimum-size tractor recommended is a 6020 Series or equivalent. For RC14R Lift-Type Rotary Cutters, the minimum-size tractor recommended is a 7720 or equivalent. Refer to the tractor's operator's manual for ballasting instructions. The pull-type versions of the RC10R Multi-Spindle Rotary Cutter require a tractor with a minimum of 50 power take-off (PTO) hp. The RC14R pull-type versions require a tractor with a minimum of 60 PTO hp. Note that the type and volume of material being cut affect horsepower requirements.

Pull type

Pull type

Pull type

Parallel lift linkage helps keep the cutter level through all height adjustments. Cylinders are John Deere manufactured, meaning more reliability and durability.

Five-year limited gearbox warranty provided on every John Deere rotary cutter

Five-year warranty on all flex-wing gearboxes

Five-year warranty on all flex-wing gearboxes

Five-year warranty on all rotary cutter gearboxes

Five-year warranty on all rotary cutter gearboxes

John Deere is so confident in the reliability of the gearbox that rotary cutters come with a 5-year limited gearbox warranty.

There is also 1-year warranty on the complete machine, including drivelines, clutches, and many other components.

Specs & Compare

Capacity | RC10R Current Model |

| Cutting width | 3,200 mm 126 in. |

| Cutting height | 25 to 305 mm 1 to 12 in. |

| Cutting capacity | 76.2 mm 3 in. |

| Cutting chamber Depth | 267 mm 10.5 in. |

Tractor compatibility | |

| Tractor PTO HP range | Minimum pull-type 37 kW 50 hp Minimum PTO lift-type 60 kW 80 hp |

| Tractor PTO | 540 rpm |

Hitch | |

| Type | Lift-Type, Pull-Type (Pull-Type has standard 10,000 lb; 4,539 kg, Safety Tow Chain) |

| Category | 2, 3, 3N |

Dimensions | |

| Transport width | 3,350 mm 132 in. |

| Overall width | 3,350 mm 132 in. |

| Overall length | 4,040 mm 159 in. |

| Deck shape | Domed |

| Deck type | Double decker |

| Deck thickness | Upper 3.5 (10) mm 0.141 (10) in. Lower 3.5 (10) mm 0.141 (10) in. |

| Side skirt thickness | 6 (3) mm 0.25 (3) in. |

| Approx. weight | 1,057 kg 2,326 lb |

Drivelines | |

| Size | Main ASAE Category 5; lift-type ASAE Category 4; pull-type |

| Protection | Main Non-seize, slip-clutch driveline pull-type has equal-angle Category 4 driveline Connecting Shock absorbing shafts |

Gearcases | |

| Number | 3 |

| HP rating | Transfer Continuous 89 kW 120 hp Peak 134 kW 180 hp Outer Continuous 75 kW 100 hp Peak 104 kW 140 hp |

Blades | |

| Thickness | 13 mm 0.5 in. |

| Width | 102 mm 4 in. |

| Type | Suction |

| Overlap | 75 mm 2.8 in. |

| Blade tip speed | 540 RPM 5,148 m/min 16,889 fpm 309 km/h 192 mph |

| Material flow system | Max flow |

| Holder | Type Round stump jumper |

Wheels | |

| Type | Laminated (Pull-type has severe-duty Ag tire option) |

| Row width adjustment | Yes |

Shielding | |

| Front | Chain |

| Rear | Chain |

Additional information | |

| Date collected | |

Key Specs | |

| Blade tip speed - 540 rpm | |

| Cutting capacity | |

| Cutting width | |

| Deck thickness - Upper - Lower | |

| Drivelines - Size - Main | |

| Hitch - Category | |

| Protection - Main | |

| Shielding - front/rear | |

| Side skirt thickness | |

| Tractor PTO HP range |