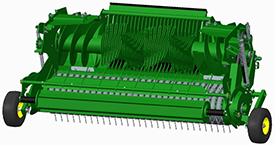

C451R

Variable Chamber Wrapping Baler

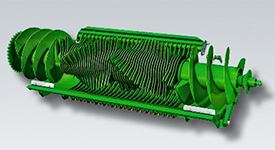

- High capacity, high performance 2.2 m wide precutter

- Wide hydraulic drop-floor clears even the worst blockage with ease

- 3 powered fixed rolls and 2 large diameter belt driving rolls inside the chamber

- Produce and wrap up to 60 bales per hour with the Fast Release System and 40 rpm wrapping arms

Features

Cam-track design offers the best versatility

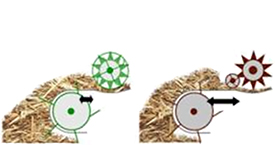

Left, pickup with cam track; right, cam-less pickup

Left, pickup with cam track; right, cam-less pickup

Cam-track technology provides an efficient solution for such needs. The traditional stripper design provides reduced space between the pickup tines and rotor feeder, while the tine motion helps to avoids pinching.

The cam-less technology requires long strippers, creating a dead zone between the tines and rotor. Additionally, fixed tines can easily pinch crops in sticky conditions, causing plugs that need to be manually removed.

The cam-track pickup features a low turning speed and big bearings on both side of the tine bars. The cam lever is made of forged steel. All these features guarantee a long component life and low maintenance.

Premium pickup pushes harvesting capacity a step forward

Premium – five tine bars – pickup

Premium – five tine bars – pickup

Tine bars made of tube and central spider reinforcement

Tine bars made of tube and central spider reinforcement

The C451R Wrapping Baler is designed for the most demanding operators. The pickup features only premium components and concepts such as:

- 2.2-m (7.2-ft) wide pickup, with a 1.92-m (6.3-ft) tine-to-tine distance - this important width provides comfort and speed capacity when harvesting the largest swaths.

- Five tine bars - the fifth bar allows the tines to rake two more times per second versus the John Deere standard four-tine pickup.

- O-shaped tubular tine bars with central spider reinforcement - tine bars are assembled with ball bearings on the central spider, and central spiders highly limit tine bars bending in the very heavy crops.

- 6mm (0.23-in.) diameter galvanized tines with high strength to harvest the toughest crops.

- Tines are designed to fold to replace potential shear bolt or cam clutch overload safety. 6-mm (0.23-in.) diameter tines push pickup maximum intake capacity up to 18 kW (24.1 hp), a value often not reached by machines using cam or shear bolt protected pickup.

- Stainless-steel strippers (exclusive feature) that give highly durable rust protection, perfect gliding capacity no matter the material, and is much more resistant to acid damage caused by additive uses (propionic acid).

Pickup design improves capacity and durability

Large-diameter stripper and five teeth bars provide high picking capacity

Large-diameter stripper and five teeth bars provide high picking capacity

Forged cam-track links improve reliability

Forged cam-track links improve reliability

The C451R and C461R Balers use the premium pickup that is also equipped on high-spec V4X1R Variable Chamber Balers. To fit all conditions, the baler is available with a 2-m (6.56-ft) or 2.2-m (7.22-ft) width.

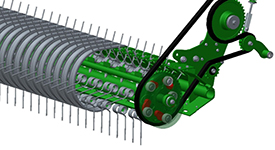

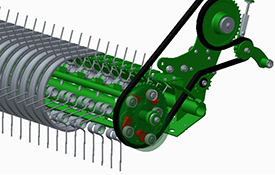

The pickup, driven by 19.05-mm (0.75-in.) heavy-duty chains, features five tubular tine bars with a low rotating speed. The large-diameter strippers allow five tine bars in the pickup. With bearings added to the cam track, all these features provide a smooth and quiet ride with extended uptime.

In addition to the high-spec features, the C451R and C461R benefit from stainless-steel strippers, a market exclusive. Stainless steel provides the following advantages:

- No rust

- Constant gliding capacity

- High resistance to aggressive additives such as propionic acids

The C451R and C461R Balers pickup uses the cam-track design, providing a better solution to harvesting wet crops. Contrary to the cam-less design, the cam track

- pickup: Features a short space between the tines and rotor, limiting dead zone

- Avoids pinching area, so no crops are plugged into the pickup drums

High-capacity (HC) rotor for higher productivity and durability

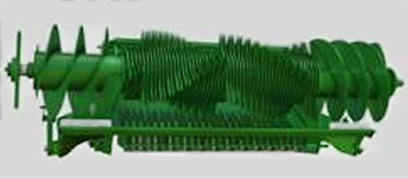

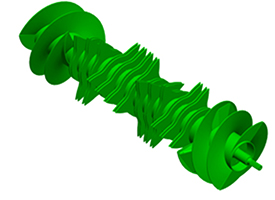

MaxiCut™ HC 25 Premium has a single axis for rotor and converging augers

MaxiCut™ HC 25 Premium has a single axis for rotor and converging augers

HC rotor limits plugs

HC rotor limits plugs

To maximize productivity in the toughest swaths, the F441R Baler features an HC Premium rotor design. Exclusive 48-cm (18.9-in.) converging augers are aligned with the rotor, limiting the free space between pickup teeth and rotor. Plugging risk is also decreased and crop transfer is highly improved. The simple HC Premium rotor design also reduces the number of moving parts and provides reliability. For example, stress on the rotor is distributed along the rotor to avoid overhang load on the bearings.

Additionally, all rotors feature tines that are made of Hardox® wear plate which drastically improves wear resistance, especially in rocky fields (Hardox wear plate tines provide 80 percent or more resistance versus traditional S700 grade steel).

The C451R and C461R are only available with a precutter, offering space between knives as short as 40 mm (1.57 in.) or 80 mm (3.15 in.).

|

MaxiCut HC 13 Premium | MaxiCut HC 25 Premium |

Number of knives |

0, 13 |

0, 12, 13, 25 |

Space between knives |

80 mm (3.15 in.) |

40 mm (1.57 in.) or |

Best use (crop type) |

Silage, hay, and straw |

Silage, hay, and straw |

High cutting quality provides better forage

Double-heat treatment for concise cut and long life

Double-heat treatment for concise cut and long life

Individual knife security for quality forage

Individual knife security for quality forage

The C451R and C461R Balers are efficient in baling a high amount of cut silage. The MaxiCut HC 13 Premium and MaxiCut HC 25 Premium feature exclusive high- quality knives, providing several advantages:

- Bulk heat treatment to reduce risk of knife breakage.

- Surface heat treatment of the cutting area to provide better cutting quality and knife durability.

A knife slot fillers set is delivered as standard with all machines featuring the precutter. When using the MaxiCut HC Premium pickup without knives, dust and harvest matter can fill knife slots. This keeps the knives from returning to the cutting position, and plugs must be manually removed to free the knives.

Select number of knives from the cab to increase uptime

Knife activation from the BaleTrak™ monitor

Knife activation from the BaleTrak™ monitor

Knife sets from the cab with MaxiCut HC 25 Premium

Knife sets from the cab with MaxiCut HC 25 Premium

The C451R and C461R can be used on several kinds of crops, in which knives can be engaged or removed. No matter the rotor type or monitor, this operation is easily managed from the cab.

When using the MaxiCut HC 25 Premium precutter, crops can be cut as short as 40 mm (1.57 in.), but only half of the knives can be engaged. This system proposes to use two different sets of knives for the same cutting width, to allow the use of sharp knives longer. By using sharpened knives versus blunt, fuel consumption can be decreased by up to 10 percent.

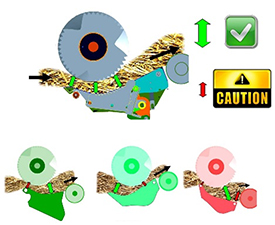

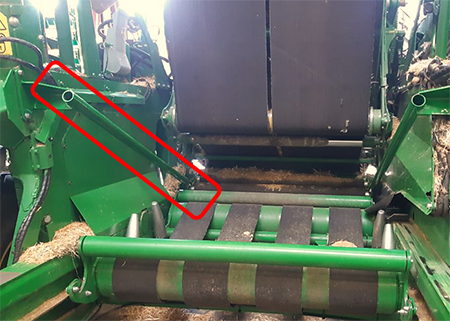

Drop floor can remove the worst plugs

Drop floor covers rotor full width

Drop floor covers rotor full width

Parallel kinematics avoids narrowing

Parallel kinematics avoids narrowing

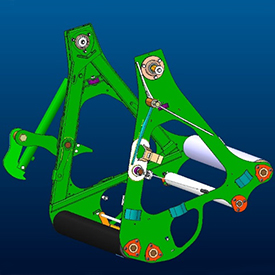

No matter the operator experience, plugs can still occur, especially with large silage swaths. The C451R and C461R are equipped as a base with a drop floor unplugging system. The drop floor features exclusive advantages, such as:

- Full-width design - by covering the full pickup width, the device can remove plugs, even located under converging augers.

- Parallel kinematic - no rear or front hinge means no narrowing. The F441R drop floor offers a constant 40-mm (1.6-in.) free space through the feeding channel when activated. This is enough to decompress the crops and avoid crop loss.

No matter the precutter or monitor type, the drop floor unplugging system can be easily managed from the cab.

Hardox is a trademark of SSAB Technology AB.

The C451R benefits from the proven HC rotor concept, featuring an in-line design

Rotor and converging augers aligned on a single axle

Rotor and converging augers aligned on a single axle

Left, HC rotor; right, classic rotor design

Left, HC rotor; right, classic rotor design

By using the HC premium rotor – a device available on John Deere round balers since 2012 – the C451R feeding system offers:

- Limited distance from the pickup to rotor tines to reduce plugging, especially in brittle straw or short silage

- Reduced number of bearings and distributed loads along the rotor to increase reliability

- Large 48-cm (18.9-in.) diameter converging augers facilitate crop transfer

The overall result is optimized crop flow that avoids all dead area where crops stay for a long time.

This smooth and regular crop flow guarantees high feeding capacity, especially in short crops such as brittle straw or sticky silage.

MaxiCut™ HC 13 Premium rotor offers standard cutting length coupled with high productivity and versatility

MaxiCut HC 13 Premium rotor

MaxiCut HC 13 Premium rotor

Knives individually protected

Knives individually protected

The C451R Wrapping Baler can be delivered with a MaxiCut HC 13 Premium rotor.

The rotor features:

- Close to 50-cm (19.7-in.) diameter rotor for high inertia and feeding capacity.

- Hardox® wear plate material (similar to R-Series) to provide a long lifespan and high resistance to foreign objects (Hardox wear plate tines provide 80 percent or more resistance versus traditional S700 grade steel).

- Three tines per turn (instead of two on G-Series RotoFlow HC)

- Tines fully enclosing the tube (instead of spikes on G-Series RotoFlow HC), giving higher tine resistance and longer component lifetime

- 0/13 knives engagement from the display. No need to leave the cab to manage knives.

- 80-mm (3.1-in.) knife spacing when all knives are engaged, a standard cutting length that gives a good compromise between crop quality and power consumption.

- Heavy-duty knives thanks to the double hardening and tempering treatment. Crops are perfectly cut for long, requiring less fuel consumption and sharpening operations.

- Individually spring-loaded knives to avoid component damages when grabbing foreign objects. Compared to a shear bolt or full-set hydraulic system, this technology limits the effort on the knives and/or provides non-stop safety.

MaxiCut HC 25 Premium provides high-quality fine chopped crops

MaxiCut HC 25 Premium rotor

MaxiCut HC 25 Premium rotor

Two knives sets can be managed from the monitor

Two knives sets can be managed from the monitor

For enhanced forage quality or for special application (poultry bedding, fruits, and vegetables application), MaxiCut HC 25 Premium can be assembled on R-Series Balers.

As with the RotoFlow HC Premium or MaxiCut HC 13 Premium, this fine chop precutter features:

- Close to 50-cm (19.7-in.) diameter rotor for high inertia and feeding capacity.

- Hardox wear plate material (similar to R-Series) to provide a long lifespan and high resistance to foreign objects (Hardox wear plate tines provide 80 percent or more resistance versus traditional S700 grade steel).

- Three tines per turn (instead of two on G-Series RotoFlow HC).

- Tines fully enclosing the tube (instead of spikes on G-Series RotoFlow HC), giving higher tine resistance and longer component lifetime.

The fine-chop precutter function offers additional features such as:

- 0/12/13/25 knife engagement from the display. No need to leave the cab to manage knives. When used alone, the 12 or 13 knives set provides a regular 80-mm (3.1-in.) knife spacing and limited power consumption. When paired together, knife spacing is reduced to 40 mm (1.6 in.).

- Heavy-duty knives thanks to the double-hardening and tempering treatment. Crops are perfectly cut for long, requiring less fuel consumption and sharpening operations. When cutting at a regular 80-mm (31-in.) length, the two independent knife sets extend time between each sharpening process by using the first knife set one day and the second one on the next day (time between each sharpening process given can vary greatly depending on crop type and number of bales).

- Individually spring-loaded knives to avoid component damage when grabbing foreign objects. Compared to a shear bolt or full-set hydraulic system, this technology limits effort on the knives and/or provides a real non-stop safety.

Hardox is a trademark of SSAB Technology AB.

Drop floor with parallel kinematic provides a constant free space to remove plugs

40-mm (1.57-in.) free space under the rotor

40-mm (1.57-in.) free space under the rotor

Parallel kinematic avoids bottleneck noticed with other concepts

Parallel kinematic avoids bottleneck noticed with other concepts

The C451R Baler comes with a drop-floor unplugging system. In case of clog, the drop floor is managed from the display simultaneously or independently from the knives. When lowering the floor, the parallel kinematic has 40-mm (1.57-in.) extra free space under the rotor and converging augers.

By providing a constant free space, the John Deere drop floor avoids bottlenecks existing on balers using movable floors with front or rear hinges. No need to have a huge opening (that sometimes causes crop loss), only a few free centimeters (inches) are enough to remove the plug.

Full-width drop floor removes clogs under converging augers

Full-width drop floor removes clogs under converging augers

The worst plugs generally happen when turning with the baler. In such situations, the crops are blocked under the converging augers and the clog must be manually removed. The unique John Deere drop floor features a full width, protecting the full pickup and rotor width. Even when plugged at the converging auger level, the clog can be easily removed by the operator from the cab.

Proven high density and bale weight

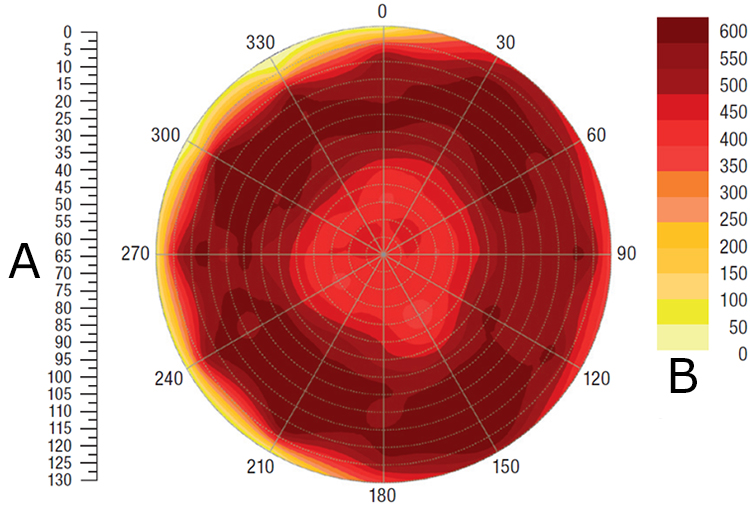

A is bale diameter (cm) symmetric across the 0-degree axis, and B is bale density (kg/m3)

A is bale diameter (cm) symmetric across the 0-degree axis, and B is bale density (kg/m3)

Deutsche Landwirtschafts-Gesellschaft e.V. (DLG) official silage bale test

| Test data | |

| Date | 23 June 2012 |

| Harvested crop | Grass silage |

| Baler | John Deere 960 |

| Bale number | 12 |

| Bale weight | 786 kg (1732.8 lb) |

| Bale density | 505.8 kg/m3 (31.6 lb-ft) |

| Bale diameter | 127 cm (50 in.) |

| Bale width | 123 cm (48.4 in.) |

| Dry matter content | 68.8 percent |

| Density setting | 100 percent |

| Number of knives | 13 |

| Driving speed | 14.3 km/h (8.9 mph) |

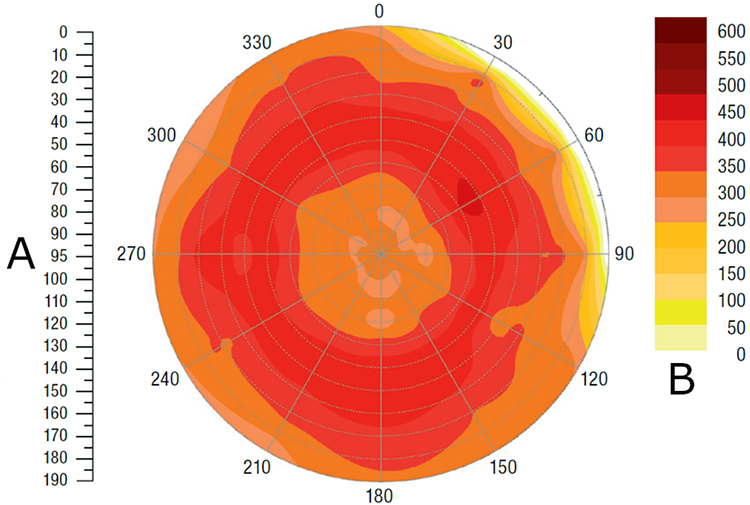

A is bale diameter (cm) symmetric across the 0-degree axis, and B is bale density (kg/m3)

A is bale diameter (cm) symmetric across the 0-degree axis, and B is bale density (kg/m3)

DLG official straw bale test

| Test data | |

| Date | 13 August 2012 |

| Harvested crop | Wheat straw |

| Baler | John Deere 990 |

| Bale number | 3 |

| Bale weight | 472 kg (1040.6 lb) |

| Bale density | 125.3 kg/m3 (7.8 lb-ft) |

| Bale diameter | 192 cm (75.6 in.) |

| Bale width | 126 cm (49.6 in.) |

| Dry matter content | 88.5 percent |

| Density setting | 100 percent |

| Number of knives | --- |

| Driving speed | 17.7 km/h (11 mph) |

The C451R can produce bales from 0.8-m (2.6-ft) diameter for non-wrapped materials or 1.0-m (3.3-ft) diameter for wrapped crops up to 1.60-m (5.2-ft) diameter with a 1.21-m (4-ft) bale chamber width. The diameter of wrapped bales can be pushed up to 1.45-m (4.76-ft).

The MaxD – Maximum Density – bale chamber has been designed to deliver very heavy, dense, and perfectly shaped bales, officially proven by DLG.

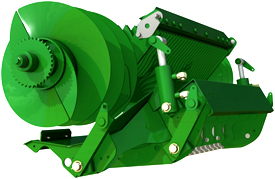

Offset density arm provides tension to the belts

Offset density arm gives tension to the belts

Offset density arm gives tension to the belts

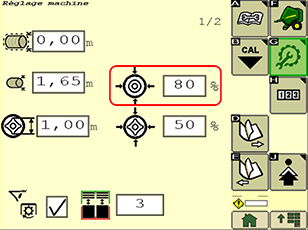

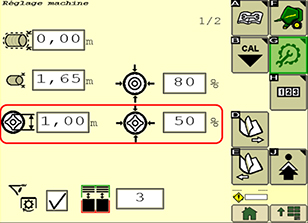

Simple density settings from monitor

Simple density settings from monitor

The C451R density is provided by an offset tension arm that applies hydraulic tension to the belts and not directly to the bale. This heavy-duty component is not involved in belt length compensation, so 100 percent of hydraulic power is involved in belt tensioning.

Density is easily set from the monitor and can be adjusted from 0 to 100 percent of hydraulic pressure. A virtual gauge located on the main working page continuously follows the density increase without looking back to the baler.

Density can also be adjusted manually from the hydraulic valve in case of major failure.

Wide endless belts provide density and reduce crop loss

Only two belts - advanced belt tracking allows the operator to work in all conditions

Only two belts - advanced belt tracking allows the operator to work in all conditions

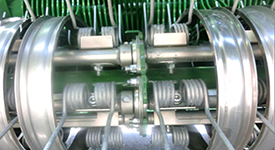

The C451R Round Balers feature two wide 573-mm (22.56-in.) belts, meaning that only three free spaces are observed (one between the two belts plus one on each belt side). Compared to a traditional 5/6 belts solution, only using two belts optimizes bale coverage by approximately 4 percent. The result is significant crop loss limitation and more efficient baling process.

To be able to handle huge stress transmitted by the density arm, the belts have no lacers.

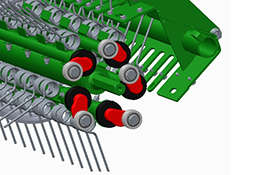

An advanced belt tracking system, including wide front pulleys and several guides located throughout the chamber, ensures accurate belt positioning, even when working in slopes or when overloading one pickup side. All edges of parts potentially in contact with the belts are chamfered to avoid belt side damage. A take-up arm manages belt tension compensation during the unloading process to avoid potential belt tracking issues.

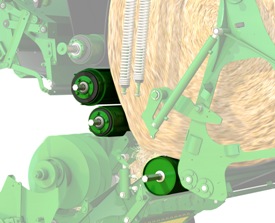

Belts are driven by two large-diameter rubber rolls with a large contact surface that avoid belt slippage in very wet conditions. Springs linked to the density arm are located on both sides of the chamber and give enough tension to the belts from bale starting.

To limit crops from sticking, belts feature a smooth pattern. Paddles on belts' driving rolls, cleaning augers into the density arm, and other scrapers located in several places through the belts paths continuously clean the belts and remove crop accumulation around the bale chamber.

Bale chamber rolls make easy bale starting in all conditions

Driven bale chamber rolls rotate crops immediately

Driven bale chamber rolls rotate crops immediately

MaxD bale chamber features three powered rolls to improve versatility and bale quality:

- The three powered rolls facilitate bale starting, especially in wet conditions such as silage. Forage immediately turns into the chamber, and there is no slipping risk even with the heaviest bales.

- Rolls are positioned to give the bale a perfectly round shape, regardless of the bale diameter, and the core is ideally centered.

- As belts push crops against rigid steel rolls, high pressure is easily applied and provides high-density bales.

Heavy-duty components team high density and durability

Reinforced bale chamber components (in red)

Reinforced bale chamber components (in red)

Heavy bales, high density, high baling speed, and high tractor power directly impacts baler durability. The C451R Round Baler includes several heavy-duty components into the bale chamber to meet growers’ expectations:

- The front part of the bale chamber (front side sheets) – the most stressed area – is made with Hardox® steel plates to limit impact of aggressive crop friction.

- Lower Fast Release System (FRS) roll handling a large part of the bale weight features extra thickness (plus 40 percent versus standard rolls) for extended durability.

- Tailgate frame is specially reinforced around the lock to handle huge tension.

- Top belts driving roll receive a special heat tempering.

Standard softcore system provides perfect crop quality

Softcore is fully adjustable from monitor

Softcore is fully adjustable from monitor

The C451R benefits from a standard advanced softcore system management:

- Bale core density (different from the overall bale density) can be adjusted from 0 to 100 percent of maximum density capacity from the monitor.

- Bale core diameter can be set from the monitor.

- Softcore system can be activated/deactivated from the display.

Accurate softcore settings allow:

- Production of better-quality forage when harvesting crops with residual moisture.

- To easily unroll core of bales.

Optional hydraulic belts scrappers clean belts in extreme conditions

Virtual view of hydraulic scrapper

Virtual view of hydraulic scrapper

Hydraulic belts scrapper installed on baler

Hydraulic belts scrapper installed on baler

Both V451R and V461R can be delivered ex-factory with optional hydraulic belts scrapper. This device limits sticky/wet/sugared crops accumulation in density arm. Thanks to the rubber pad, this cleaning system is particularly gentle with belts. Scrapper is automatically deactivated during bale ejection.

For enhanced lifetime, scrapper can be manually shut-off when baling dry materials.

Code |

Description |

8170 |

Hydraulic belts scrapper |

Hardox is a trademark of SSAB Technology AB.

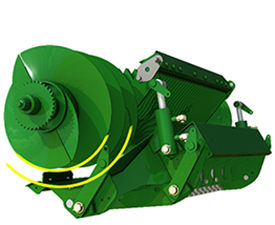

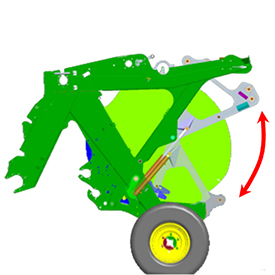

Why each second counts

The size of the tailgate directly impacts bale transfer time, and the bale chamber unloading system is a critical component in a wrapping baler.

John Deere FRS greatly decreases non-productive time and directly boosts overall baler productivity. As summarized by an official DLG Fokus test 6112F: "The signature trait of this baler is the innovative ejection system, which provides considerable advantage through a very short bale ejection time. This shortens the hold time of the baler during ejection, which can consequently lead to a higher rate of productivity."

There is an advantage to the baler compactness: by using a vertical folding structure, the C451R allows a quick transfer right after the bale has been unloaded from the chamber. FRS can close as soon as the bale leaves the unloading areas and the picking process can restart a short time after the bale has been ejected from the chamber.

On all other wrapping balers, the bale must first reach a far enough position before the tailgate can close (to avoid bale/tailgate interference risk). This transfer requires time and keeps the baler wrapping from restarting quickly.

Lighter tailgate means faster tailgate

Simple parts to move to open the tailgate

Simple parts to move to open the tailgate

230-kg (507-lb) FRS can be moved quickly

230-kg (507-lb) FRS can be moved quickly

FRS provides a light structure, less than half of the traditional tailgate weight that opens the chamber quickly and removes belts from the bale.

Compared to a traditional tailgate:

- FRS can be actuated by fast cylinders with reduced dampening needs.

- FRS impacts the baler’s lifetime in a reduced way. Moving less than 250 kg (551 lb) puts less stress on the frame than moving 600 kg (1322.8 lb) in a similar time.

- FRS pivot is located at the center of the chamber, not on the top of the baler. Motion is even faster, and center of gravity is not impacted much by tailgate position.

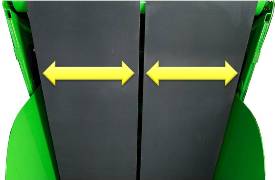

Moving side sheets release the bale faster

Side of the chamber moves

Side of the chamber moves

Moving side sheets help prevent the bale from getting stuck in the chamber. When the light structure opens, each side of the chamber automatically moves 50 mm (2 in.). There is no more contact between the bale and the chamber; the bale is released and quickly falls by its own weight. Even in the worst wet conditions, the unloading process is as efficient as in dry straw.

This unique feature does not require complicated hydraulic or mechanical systems to be actuated. When the tailgate goes down, simple bearings push on cams located on both side sheets and lock the chamber sides in the baling position. When the tailgate opens, the pressure on the side sheets cam is automatically released, then a return spring quickly moves the chamber walls outside.

Locks located on both baler side lock the FRS when tailgate is closed.

Balanced cycle time between baling and bale wrapping functions is key

Very high-speed wrapping arms

Very high-speed wrapping arms

The design of a very efficient and productive baler is not sufficient if the film wrapping unit is not able to follow the same rhythm of work. John Deere engineers came up with smart solutions to eliminate bottle necks and boost total productivity.

The core trick to achieve such productivity is in an innovative and powerful hydraulic motor which can drive the film wrapping arm over 35 rpm speed (a record on the market) and without any compromise for operator safety, as an integrated and automatic brake could stop every motion in a short time.

Changing film rolls is quick and easy

12 film rolls can be loaded on the C451R and C461R

12 film rolls can be loaded on the C451R and C461R

The C451R and C461R are equipped with a unique film roll storage device. Each film roll weighs about 20 kg (44 lb) and must be changed very often; this system has been designed to simplify loading and unloading operations.

On each side of the machine, five rolls are installed on a moving arm, hydraulically piloted. Managed by a control panel standing on both sides of the baler, the system prevents the operator from running from the left side to the right side to operate storage racks, as is the case on several competitive wrapping balers. The loading/unloading position has been set up to be as close as possible to the wrapping arms at a very ergonomic height.

Details count: in the transport position, the film storage device is covered by a roof which protects film rolls from rain. This protects the film roll core, often made of cardboard, from damage.

High efficiency even in slopes

Bale transfer slop kit

Bale transfer slop kit

To improve and secure bale transfer when working in very hilly condition, a bale transfer slope kit is available as option or attachment. Two tubes gently guide the bale to the wrapping area while dedicated cams limit side sheets opening, preventing the bale from going askew.

All settings from the monitor

Main page with simple and clear pictograms

Main page with simple and clear pictograms

No need to leave the cab to adjust the baler

No need to leave the cab to adjust the baler

The C451R Wrapping Baler uses ISOBUS architecture and can be fully set from the display. There is no need for the operator to leave the cab, even for density or greasing parameters (when equipped with optional automatic greasing system), as everything is managed from drop-down menus.

The C451R offers:

Baler Settings

- Knife engagement/disengagement

- Knife set management (when equipped with MaxiCut™ HC 25 Premium)

- Drop floor lowering/raising

- Bale diameter adjustment

- Bale density adjustment (0 to 100 percent capacity)

- Softcore activation/deactivation

- Softcore pressure adjustment (0 to 100 percent capacity)

- Softcore diameter adjustment

- Net/twine choice

- Automatic/manual tying/wrapping starting

- Manual net/twine cylinder control

- Net layers adjustment

- Net tying delay adjustment

- Twine turns on each side (independent) adjustment

- Twine spacing adjustment

- Twine space to the edges adjustment

- B-Wrap® wrapping system mode activation

- Automatic greasing system engagement/disengagement (when equipped with optional automatic greasing system)

- Automatic greasing duration and frequency

Wrapping unit settings

- Automatic/manual tailgate opening and bale transfer

- Transport table speed curve

- Number of film layers

- Automatic/manual wrapping

- Wrapping arm speed curve

- On the go/when stopped/manual/grouper mode dumping

- Dumping speed curve

- Lighting (side lights/beacon) control when option selected

Baler information

- Bale shape indicators

- Current bale diameter/set bale diameter

- Current bale density/set bale density

- Knife set position

- Drop-floor position

- Near full alarm

- Stop indicator

- Net/twine choice

- Net/twine process status

- Tailgate status

- Softcore status

- Bale counters (10 operators x 10 fields = 100 counters)

- Time counter

- Clear error message

Wrapping unit information

- Transport table position

- Wrapping arms position

- Wrapping process status (number of applied layers)

- Dumping status

- Greasing status

- Lighting status

4240 Universal Display enhances operator comfort

4240 Universal Display with C451R main working page

4240 Universal Display with C451R main working page

GreenStar 4240 connection using cab harness (delivered with)

GreenStar 4240 connection using cab harness (delivered with)

GreenStar 4240 connection using corner post harness (delivered with)

GreenStar 4240 connection using corner post harness (delivered with)

The C451R can be delivered with various monitors. At the top of the baler range, the 4240 Universal Display can be ordered. This monitor features a 21.5-cm (8.5-in.) diagonal color display. The touchscreen offers an intuitive and user-friendly interface that easily allows operators to adjust and control various settings.

The 4240 Universal Display offers extended capabilities for guidance, spraying management, farm management, and FarmSight™ applications. To be used with ISOBUS or non-ISOBUS tractors, the 4240 Universal Display option is delivered with the following components:

- 4240 Universal Display

- Baler to rear tractor ISOBUS plug

- Baler ISOBUS plug to display harness – plugged into tractor battery

- Tractor cab corner to monitor harness

The operator's own ISOBUS monitor can be used to optimize cost of acquisition and/or comfort

Connection from the baler to the built-in display in the tractor cab

Connection from the baler to the built-in display in the tractor cab

For operators already using a built-in or external ISOBUS certified display, the C451R Baler can be delivered without a monitor. Thanks to the ISOBUS connectivity, just plug the baler to the tractor/monitor and bale.

B-Wrap is a trademark of Tama Plastic Industry.

Specs & Compare

Key Specs | C451R Current Model |

| Belts-other - width | Two endless belts |

| Density control | Density and diameter fully controlled from the monitor |

| Bale size indication | Monitor |

| Regular pickup - Bars | Five |

| Regular pickup - Number of teeth | |

| Regular pickup - Tooth spacing | |

| MegaWide Plus pickup - Number of regular teeth | |

| MegaWide Plus pickup - Number of mega teeth | |

| High-capacity pickup - Number of middle teeth | |

| High-capacity pickup - Number of mega teeth | |

Bale | |

| Size | Diameter 0.8 to 1.6 m 2.6 to 5.25 ft Width 1.21 m 3.97 ft |

| Weight | |

Baler | |

| Base weight | 6803 kg 15,000 lb |

| Weight | |

| Length | 763.4 cm 300.55 in. |

| Height | 321.9 cm 126.75 in. |

| Width | With narrowest tires - 2.83 m 9.3 ft With widest tires - 3.29 m 10.79 ft |

Bale forming | |

| Forming chamber | Variable - two endless belts + two front rolls + starter roll |

| Belts-other | |

| Enclosed percent of bale surface | |

| Belt splices | |

| Density control | Density and diameter fully controlled from the monitor |

| Bale size indication | Monitor |

| Bale Shape | |

Regular pickup | |

| Width | 2.2 m 7.2 ft |

| Drive | |

| Bars | Five |

| Number of teeth | |

| Tooth spacing | |

| Lift control | Hydraulic |

| Gauge wheels | Fixed or castor action |

| Stripper diameter | |

MegaWide Plus pickup | |

| Type | |

| Width | |

| Drive | |

| Bars | |

| Number of regular teeth | |

| Number of mega teeth | |

| Tooth spacing | |

| Lift control | |

| Gauge wheels | |

| Stripper diameter | |

High-capacity pickup | |

| Type | |

| Width | |

| Drive | |

| Bars | |

| Number of middle teeth | |

| Number of mega teeth | |

| Tooth spacing | |

| Lift control | |

| Gauge wheels | |

| Stripper diameter | |

Wrapping system | |

| Control | From monitor |

| Type | Standard Net tying only Capacity for three net rolls Net system on front of baler |

| Twine arms | |

| Twine ball capacity | |

Monitor | |

| Monitor console for tractor | ISOBUS |

| Gate closed | Yes |

| Bale forming | Yes |

| Bale size | Yes |

| Near full bale | Yes |

| Full bale | Yes |

| Twine arm position Indicator | |

| Auto wrap | Yes |

| Oversize bale | Yes |

Surface wrap | |

| Available | |

Tire size | |

| Standard | |

| Optional | 500/45-22.5 tandem 620/40R22.5 tandem |

Driveline | |

| Drive protection | Cam clutch |

| PTO speed | 540 or 1000 rpm |

| Type | |

| PTO lockback collar on tractor hookup | Yes |

| PTO 60-degree free rotation | Yes |

Tractor Requirements | |

| Minimum PTO | 90 kW 120 hp |

| Hydraulic SCV valves | Power beyond is preferred but not mandatory |

Silage baler features | |

| Starter roll scraper | |

| Powered scraping auger | |

| Spirals on gate roll | |

| Pre-cutter/slicer | |

Additional information | |

| Maintenance chains | Automatic chain lubrication is standard Bearings greasing - automatic greasing system (tank) |

| Date collected | 9 August 2019 |